Micro Tunneling

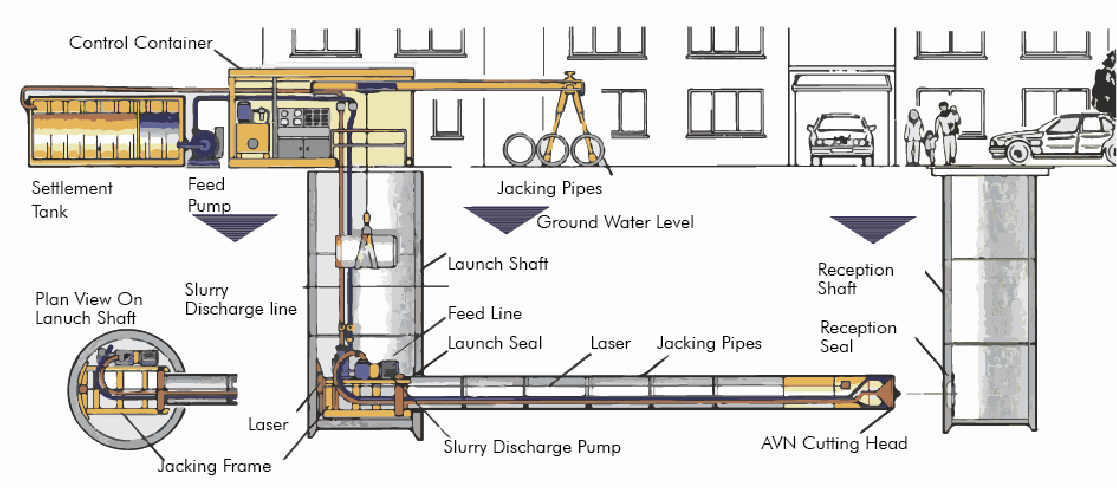

Construction of pipe lines utilizing the non-disruptive method using micro tunneling technologies Precise control of line and grade is accomplished using the guidance system and steering jacks to locate and steer the MTBM during a micro tunneling drive. The guidance system usually consists of a reference laser mounted in the jacking shaft, which transmits a beam onto a target mounted inside the articulated section of the MTBM.

As the pipeline could be installed in two ways: (a) by encasing the carrier pipe which in most cases GRP/GRE with a reinforced concrete and jack it directly to the correct line and level or (b) by jacking a steel or RC pipe as a sleeve, installing the carrier pipe in side it and grouting the annulus space by a non-shrink grout or a foam concrete.

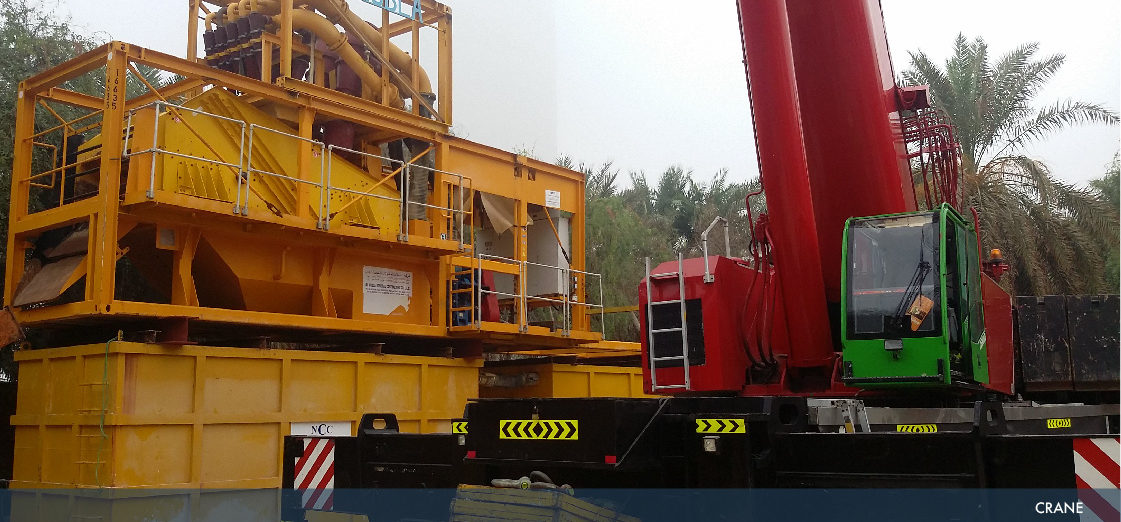

Al Nubla is a capable to carry out all pipeline diameters using of ISEKI TCC 600, ISEKI TCC 800, HERRENKNECHT AVN 600, AVN 800B, AVN 800A, AVN 1000, AVN 1200, AVN 1400, AVN 1600, AVN 1800 & AVN 2500 micro tunneling machines in diverse ground conditions, with and without ground water tables at different soil strata.

Mission

To perform for our customers and deliver the projects with the highest standard quality, services and excellence in a timely manner.

Vision

We have focused on implementing process and procedures that enable us to be more efficient and responsive as we continue to grow, and at the same time allowing us to provide our clients with that latest technology and best quality and services.

Core Value

While our commitment to the advances in technology put us at the forefront of the tunneling business, we acknowledge that this would not be possible without our staff. We take pride in our expert staff and highly trained and experienced operators and their commitment to the company and to our valued clients. We have and continue to invest in our staff by developing ongoing training programs because we firmly believe that the long term success and sustainability of a business is directly linked to its management and staff.

THE PROCESS OF Microtunneling

The basic procedure for microtunneling.

Once the setup of the jacking frame and surface equipment is complete, the jacking operation can commence.

We here above describing the basic procedure for microtunneling.

Alignment Control – Prior to launching the machine a laser is fixed in the pit bottom. This laser is aligned to the correct horizontal alignment and vertical grade in a position that ensures it shines onto the laser target within the machine. The laser target within the machine detects the laser beam through a series of light sensors and is able to determine the position of this beam. This information is relayed to the control cabin and a graphical display indicates the horizontal and vertical position of the machine to the operator. The machine itself is articulated and the angle of this articulation is controlled by hydraulic cylinders. By opening and closing the cylinders the operator is able to control both the vertical and horizontal direction of the cutter head. It is this control that allows the operator to ensure the laser beam remains on the target throughout the length of the tunnel drive and therefore the machine and pipeline remain within design tolerances. Machine Launch and Excavation Procedure – Each machine consists of 2 main parts, or ‘cans’, the machine can and the trailing can. The machine can is the front part of the machine and contains all the mechanical components such as the cutting wheel, main drive motor and gear box. The trailing can is empty and is there to prevent any rolling of the machine being transferred to the pipe, there are injection ports in the trailing can that allow bentonite lubrication to be injected very close to the machine if required.